Manufacturing and sale of industrial doors, overhead crane doors, polyethylene doors

Discover our partition walls made of PVC: they allow you to create and divide working areas quickly and flexibly!

PVC rolls are an extremely popular and functional solution in the industrial sector, thanks to their versatility, resistance and insulating properties. They are used in numerous production and logistics contexts, especially for the creation of flexible barriers, strip curtains, protective coverings and industrial doors.

APPLICATIONS

PVC strips are extremely easy to use and to work with.

- Flexible walls

- Fixed or movable striped walls

- Strip curtains

- Doors for cold rooms (for temperatures down to 0°C)

- Doors for cold rooms (for low temperatures down to -30°C and -60°C)

- Partitions for refrigerator aisle

- Noise protection panels

- Dust protection panels

FLEXIBLE PVC ROLLS INFORMATION SHEET

-

Flexible PVC rolls information sheetFlexible PVC rolls information sheet

-

Flexible PVC rolls galleryFlexible PVC rolls gallery

OCM FLEXIBLE PVC ROLLS

In-house production

Our products are designed and manufactured entirely in Italy at our Biella factory.

Team of Engineers

Team of engineers, designers and specialised technicians at your service to propose the best solutions.

Network of Agents

A network of agents in Italy and abroad is constantly expanding.

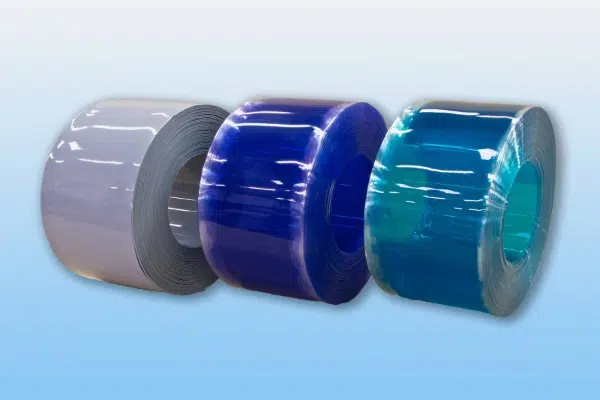

ROLLS TYPES

Standard

It is made from the standard version of PVC, which is transparent and flexible.

It is suitable for applications in food preparation areas and where there may be contaminants or dust problems.

PVC for low temperatures

This type of PVC is made from a mixture that enables the material to withstand even very low temperatures (-40°C).

It is also suitable for applications in food preparation areas and where there may be contaminants or dust problems.

Coloured PVC

This roll is made of matt black PVC, perfect for acting as a barrier between different areas.

It can be applied both externally and internally, in environments varying in temperature from -20°C to 70°C.

It can be useful in many cases.

Anti-static PVC

Specially designed to be applied in areas of high static intensity.

It can be installed both internally and externally.

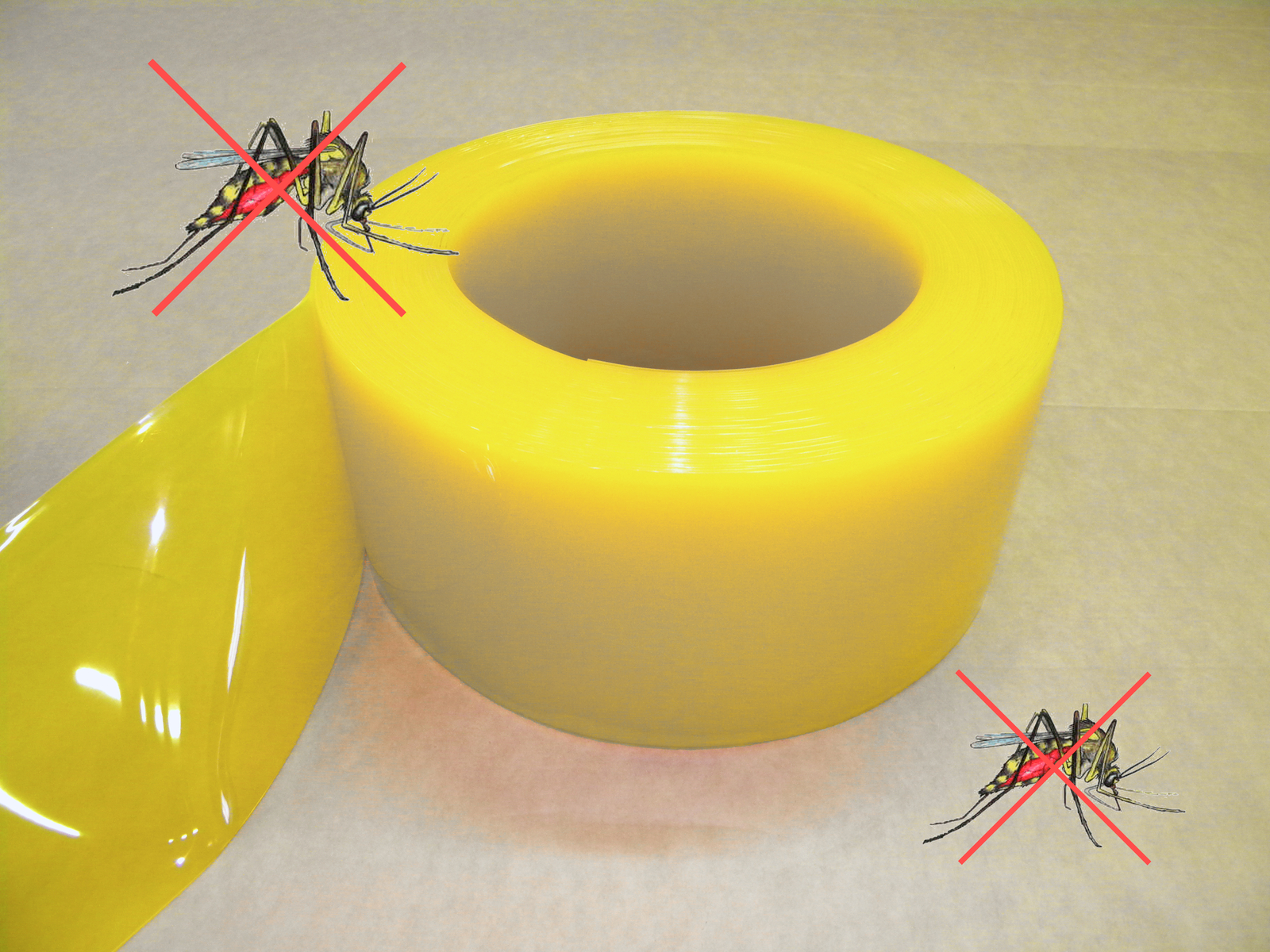

Anti-insect PVC

This yellow roll is made using Citronella and is specially designed to prevent flying insects (gnats, mosquitoes, etc…).

This type of roll also blocks UV radiation, making it the ideal solution for a wide range of applications.

It can be applied both externally and internally, in environments varying in temperature from -20°C to +70°C.

COLOURS

- Matte orange

- Matte white

- Matte blue

- Translucent blue

- Matte grey

- Translucent yellow

- Matte black

- Translucent red

- Frosted PVC

- Dark green bottle effect